We are the leading manufacturer of stern tube shaft sealing devices worldwide with our products installed on over 30,000 ship of 100 gross tonnages or more. The Marine Ace Seal (MAS) is our newly developed waterlubricated stern seal for small vessels with direct drive systems.

Features

- Excellent vibration resistance and sealing performance

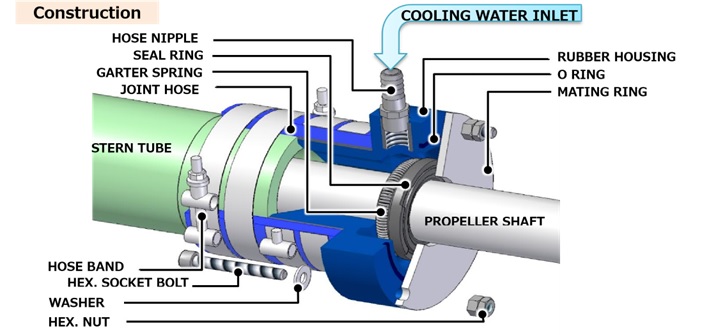

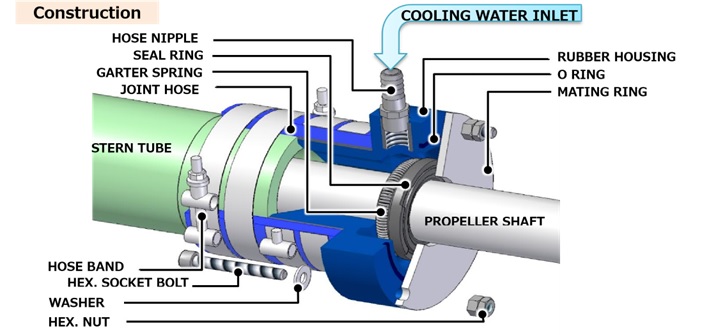

- Due to an end-face seal structure consisting of a rubber sealing ring and a stainless steel mating ring, it is able to follow complex shaft vibration and displacements thereby demonstrating an excellent sealing performance.

- Excellent followability in the axial direction

- As sealing is achieved by the seal ring rotating at the same speed as the shaft and its face structure making contact against the stationary mating ring as a stopper, it is able to absorb all axial movement.

- Simple and robust rubber housing design

- The inner diameter of the housing is designed to the same high standard as a rubber bearing so it can withstand contact with the shaft is lowered. As the sealing area is not exposed externally as is the case with a mechanical seal, it is able to withstand ‘mechanical shock’ to a high degree.

- Easy to install

- The installation space is compact with the structure requiring only the cooling water hose to be supplied. The structure is fixed to the stern tube by means of two hose bands making it simple to install.

- Excellent slurry resistance

- The seal can be expected to have a long life even under dirty water conditions with a high degree of sediment as found in shallow water and rivers.

Design Outline

- Shaft Range :

- φ45~φ85 (5mm increment), 2”~3” (0,5”increment)

- Allowable PV Value :

- 0.3 MPa・m/sec P (Pressure in sealing device) : Max. 0.1 MPa

V (Shaft rotation speed)

- Required amount of cooling water :

- Min. 3 Litter/min

- Temperature of cooling water :

- 0~40℃

(mm)

| Shaft Dia. (mm) A |

MASTypeNumber |

Stern TubeO.D.(mm) B |

Conn.Len.(mm) D |

MASO.D.(mm) E |

MASLen.(mm) F |

O RingSize(mm) G |

Mass.(kg) H |

| 45 |

MAS045 |

89.1 |

50 |

150 |

170 |

3.5X104 |

2.7 |

| 50 |

MAS050 |

| 50.8(2") |

MAS051 |

| 55 |

MAS055 |

101.6 |

60 |

165 |

180 |

3.5X117 |

3.2 |

| 60 |

MAS060 |

| 65 |

MAS065 |

114.3 |

70 |

180 |

190 |

3.5X127 |

3.7 |

| 70 |

MAS070 |

| 63.5(2/5") |

MAS063 |

| 75 |

MAS075 |

127 |

80 |

195 |

220 |

3.5X152 |

5.0 |

| 80 |

MAS080 |

| 85 |

MAS085 |

| 76.2(3") |

MAS076 |

- *1 MAS051/MAS063/MAS076 are for inch shafts

- *2 Please note that other non-standard size can be manufactured upon request.

Fig2. Components & Materials

| No. |

Part Name |

Material |

Qty. |

Remarks |

| 1 |

Seal ring |

Rubber NBR |

1 |

|

| 2 |

Garter spring |

Stainless steel |

1 |

|

| 3 |

Mating ring |

Stainless steel |

1 |

|

| 4 |

Rubber housing |

Rubber IR |

1 |

|

| 5 |

Joint hose |

Rubber CR |

1 |

|

| 6 |

O ring |

Rubber NBR |

1 |

[See G] |

| 7 |

Hex. Socket bolt |

Stainless steel |

4 |

M8 |

| 8 |

Hex. nut |

Stainless steel |

4 |

M8 |

| 9 |

Hex. nut |

Stainless steel |

4 |

M8x60(70) |

| 10 |

Plain washer |

Stainless steel |

4 |

|

| 11 |

Hose nipple |

Stainless steel |

1 |

PT3/8 |

| 12 |

Hose band |

Stainless steel |

4 |

|

- *The value in the parentheses indicates over 75mm shaft dia.